Today’s B2B manufacturing world moves at breakneck speed, yet businesses still expect every part to fit perfectly on the first try. CNC precision turned parts sit at the center of that dilemma, giving the backbone to many high-end machines and tools. In sectors where failure is not an option-aerospace, medical tech, or defense-working with reliable precision CNC machining shops is the only way to hit tight specs and keep promised ship dates.

The Role of CNC Precision Turned Parts in High-Precision Industries

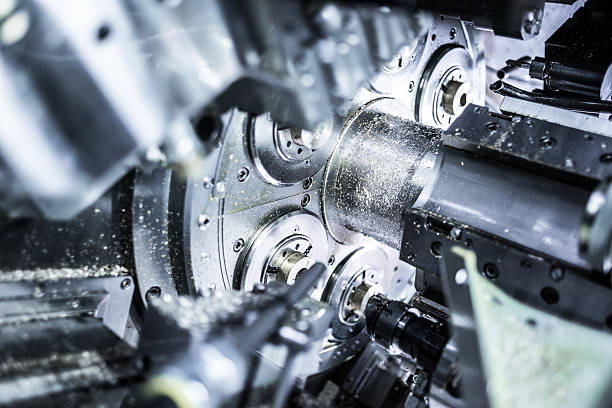

CNC turned components show up wherever absolute repeatability is the rule. Aerospace, medical devices, telecom gear, robotics, defense systems, and sensitive electronics all rely on these small but mighty pieces; a single bad unit can ground a plane, halt surgery, or crash a network.

Parts in these markets often have complex shapes, tolerances that shrink to microns, and finishes polished to mirror-like smoothness. Be it a tiny titanium plug tucked inside a satellite or a rugged stainless-steel valve feeding a chemical line, CNC precision turned parts must deliver the same performance every time, matching exact angles, weight, and strength without exception.

Top precision CNC machining shops now tackle jobs that demand both clever engineering and tough materials-including Inconel, titanium, brass, and hardened steels. This mix of requests is pushing turned-part makers to rethink how they work.

Balancing Speed and Accuracy Through Advanced CNC Technology

Getting parts right again and again while still shipping them fast is no easy feat. Shops meet the goal by leaning on new machines and smart automation. Modern multi-axis CNC lathes that turn, mill, drill, and thread in one pass cut the number of setups, slash errors, and trim cycle time.

Forward-looking precision CNC manufacturers use several key tactics:

- Dual-spindle and live-tool lathes let operators run two actions at once, so parts spend less time spinning in place.

- High-speed, high-torque spindles clear chips fast and stay cool under load.

- In-machine metrology systems check sizes as the work happens, not after, so every piece stays within spec.

In a smart factory, every step on the production line talks to the next through Internet-of-Things sensors and a single dashboard. Cutters change speed and path in the moment, guided by live feedback, while smart alerts spot worn parts before they break. That loop lets makers crank up accuracy without slowing delivery-deadline, a must for OEMs and Tier-One shops living under tight contracts.

How Quality Control Safeguards Tight Tolerances

Shipping CNC parts to the last micron isn’t just about a killer machine; it also needs strict checks, clear history, and steady rules. In high-risk fields such as aerospace or med-tech, letting one fault slip is simply not an option.

Precision CNC machining houses rely on several tools:

- In-process and final checks, with gear like automated optical inspection (AOI) and 3D laser scanners.

- Coordinate Measuring Machines (CMMs) that record every surface and angle with mirror-like accuracy.

- Gauge calibration rigs that verify every micrometer and fixture stays true shift after shift.

Manufacturers often rely on statistical process control (SPC) to track part dimensions while the job runs. Catching small errors early lets engineers tweak the machine code and tightens the tolerances. Keeping clear records and being able to trace every step is especially important when the parts must meet FDA rules or ISO quality standards.

Material Flexibility: From Soft Metals to High-Strength Alloys

For a turning shop to win repeat work, it must cut many different materials without losing accuracy or speed. Soft metals such as aluminum or brass call for a defined set of tools and feeds, while tougher grades like tool steel or nickel superalloys need something entirely different.

Smart operators remember

- Thermal expansion, which can change a part size while the spindle is still turning

- Vibration and deflection, especially in long or slender components

- Material-specific wear that dulls cutters at uneven rates

To stay ahead, leading plants write programs for each alloy, balance the tooling set, and watch tool life in real time. Some even run adaptive systems that store how a given metal reacts, so every batch behaves the same from start to finish. With this level of control, they can confidently slot precision CNC turned parts into mixed-material assemblies.

The Future of CNC Turning: Digital, Agile, and Connected

CNC turning is changing fast, thanks to Industry 4.0. As smart factories become the norm, precision CNC machining shops are finding new ways to make custom parts at scale, use less power, and cut prototype times.

Emerging trends include:

- Hybrid systems that mix additive and subtractive work: print a rough shape and finish it with exact CNC turning.

- AI-driven CAM programs that watch every cut and tweak the tool path for quicker cycles and smoother surfaces.

- Digital twins that let workers run a virtual part under load, lowering design risk and boosting yield.

- Modular robot cells that easily switch to batch-one jobs and keep short runs moving at factory speed.

All these tools let machine shops turn parts faster, try more daring designs, and spend less on overhead. B2B buyers, in turn, get swifter replies to updated specs, tighter tolerances on complex pieces, and greater trust that the supply chain will deliver.

Wrap-Up

CNC precision turned parts don’t just roll off machines in bulk anymore. Thanks to today’s heavy dose of data and connected tools, they now come off the lathe carrying serious design work and tight tolerances every single time. Forward-thinking precision CNC machining manufacturers are plowing money into real-time quality checks, smart robots, and adaptive setups because their B2B customers keep asking for speed, steady repeatability, and costs that don’t spiral.

As factories hunt for lighter, smaller, and trickier assemblies, CNC turning will still sit at the heart of the process. It’s just that the job is getting done with quicker setups, wittier machines, and software that talks seamlessly through the whole product pipeline. For any company that needs parts built within a whisker of the blueprint, picking the right machining partner has become a key business move.

YOU MAY ALSO LIKE: Everything You Need to Know About Intel-Based Servers